There are three advantages of tabletop MAP tray sealer. The first advantage is that it is the electrical drive. Our old type is pneumatic, and the machine needs to install an air compressor inside. An electrical drive can solve the problem of an air compressor. There is no doubt that it can save money for customers. Certainly, you will pay attention to its power consumption. Please don’t worry about it. The machine consumes electricity normally. The second one is that the structure of the machine is compact. They are film, mold, and the control panel from top to bottom. The third one is that it is affordable. You can get the same packing effect as the floor-type MAP machine. The tabletop machine can support adding one gas to the tray.

1.Fault real-time reminder function

2.Pack count function

3.Precise film running system

4.Tool-free mold replacement

Technical Parameter of the Modified Atmosphere Packaging Tray Sealer,DJT-400G

| Model |

DJT-400G |

| Max. Tray Dimension(mm) |

330×220×70 |

| Max. Width of Film(mm) |

390 |

| Max. Diameter of Film(mm) |

220 |

| Packing Speed(cycle/min) |

4-5 |

| Air Exchanging Rate(%) |

≥99 |

| Electrical Requirement(v/hz) |

220/50 110/60 |

| Consume Power(kw) |

1.8 |

| N.W(kg) |

92 |

| G.W(kg) |

120 |

| Machine Dimension(mm) |

690×850×750 |

| Shipping Dimension(mm) |

750×900×850 |

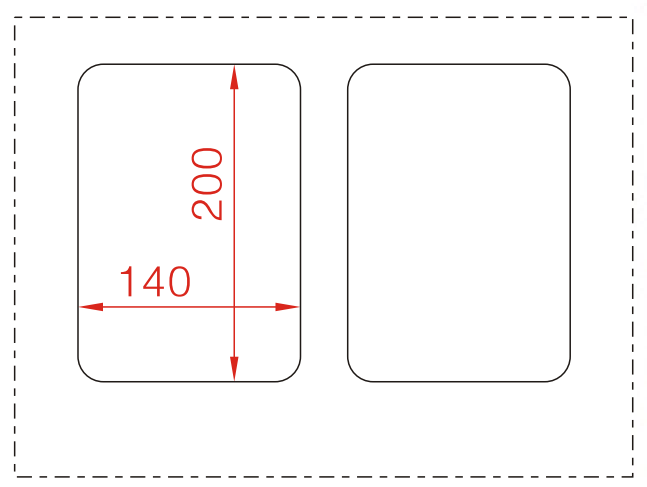

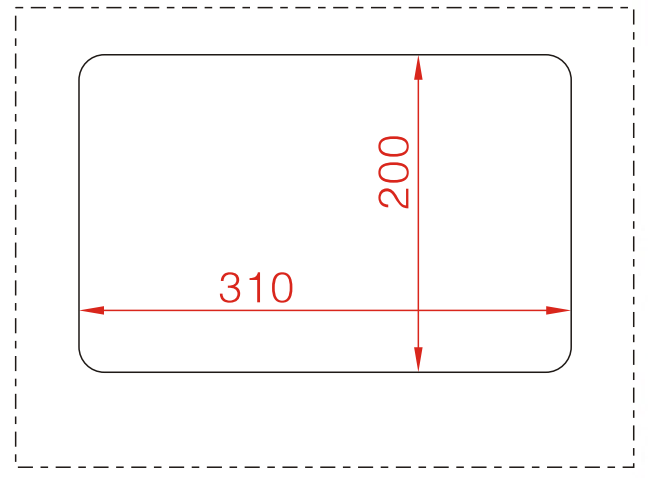

Max. Mould(Die Plate) Format(mm)

Full Range of Version Tabletop MAP Tray Sealer Machine

|

MODEL |

THE MAXIMUM OF TRAY SIZE |

|

DJT-270G |

310×200×60mm(×1) 200×140×60mm(×2) |

|

DJT-400G |

330×220×70mm(×1) 220×150×70mm(×2) |

|

DJT-450G |

380×230×70mm(×1) 230×175×70mm( ×2) |